Precision Bench Scale for Accurate Workbench Weighing

Dwinley‘s precision bench scale supports industrial, laboratory, and professional work that depends on accurate measurement. It delivers stable readings and fine resolution for small parts, samples, and controlled materials. It works on any workbench or tabletop and fits workflows that require dependable accuracy every day.

- LCD with backlight display

- High precision to weighing

- RS232 and 6v/4.5ah battery included.

- Programmable to meet your needs

- Unit swtich,counting,weighing check,Percentum mode,

- Auto zero-setting when switch on the scale

- Auto zero-tracing,Setting Alarm function,rs232,blue tooth etc.

Specifications of Dwinley Precision Bench Weighing Scales

| .Display | 20mm digit LCD display,with white LCD backlight |

| .Capacities | 3kg~30kg |

| .Pan Size | 227x280mm |

| .Keyboard | 9keys |

| .Unit | kg/g/lb |

| .Housing | ABS plastic |

| .Max. Divisions | 60,000d~75,000d |

| .Operate Tem | 0ºC ~ +40ºC |

| .Power | AC adapter(8v/500mA),internal rechargeable battery (6V/4.5Ah) |

| .Gross weight | 3.5kg |

| .Packing | Master carton packing,dimension 0.022m³ |

| Master carton 5 in 1 packing,dimension 0.108m³ |

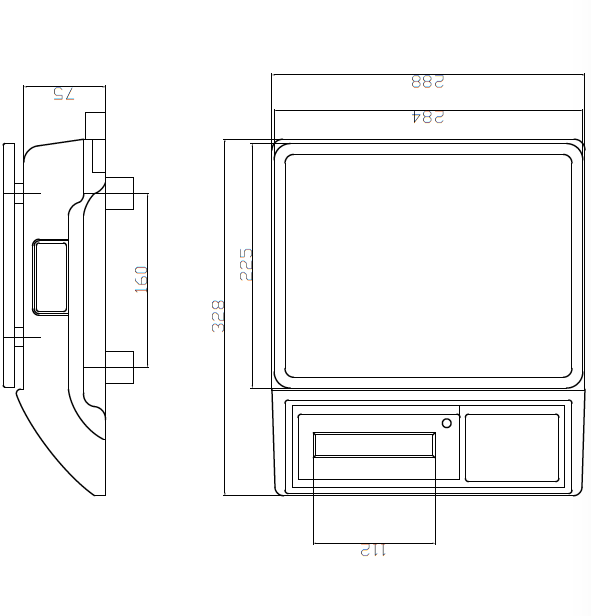

Dimensions(mm)

JCS-BI High Precision Weighing Scales

| Model Number | Capacity | Readability | Division | Approval |

|---|---|---|---|---|

| JCS-3BI | 3kg | 0.05g | 60,000d | CE |

| JCS-6BI | 6kg | 0.1g | 60,000d | CE |

| JCS-15BI | 15kg | 0.2g | 75,000d | CE |

| JCS-30BI | 30kg | 0.5g | 60,000d | CE |

Your Reliable Wholesale Partner for Precision Bench Scales

Dwinley manufactures high quality bench weighing scales for buyers that need accuracy and stable performance. We support wholesale, OEM, and private labeling to help you grow your product line with confidence. Send us your inquiry to get pricing and customization options. Our team is ready to support your brand from concept to delivery.

What Is a Precision Bench Scale?

A precision bench scale is a compact weighing device designed for tasks that need higher accuracy than a standard bench scale. It handles small items with clarity and repeatability. It also supports tasks that require frequent testing, measuring, or recording of weight with fine detail.

This type of scale is used in small manufacturing units, electronics workshops, QC departments, research labs, and jewelry processing environments. These areas rely on consistent results. A precision bench scale meets those demands with stable performance and clear readings.

Key Features of a Precision Bench Scale

High-Accuracy Measurement

Accuracy defines the purpose of a precision bench scale. It offers a fine resolution such as 0.1 g or 0.01 g depending on the model. This resolution helps users track small differences that matter during production or testing. It also supports repeated weighing with minimal fluctuation.

Stable Sensor System

The scale uses a sensitive load cell that maintains steady readings. This stability helps users confirm data through repeated tests. It also supports environments where operators must measure multiple items without losing accuracy.

Clear Display and Easy Operation

A precision bench scale includes a clear digital display. The numbers appear instantly without heavy lag. The simple control panel supports tare, unit conversion, and calibration. These functions help users operate the scale without difficulty.

Reliable Calibration Options

Maintaining accuracy is essential. A precision bench scale supports external calibration weights or built-in calibration depending on the model. This helps users keep readings correct throughout the scale’s service life. Proper calibration supports inspections, sample work, and controlled production steps.

Why a Precision Bench Scale Matters in Professional Work

Consistent Weight Control

Certain industries must track weight variation with accuracy. Even a small error can affect product quality or material use. A precision bench scale helps businesses control each step. It delivers reliable results that support stable workflow operations.

Reduced Errors and Waste

Accurate weighing helps reduce material waste. It avoids mistakes caused by inaccurate measurements. It also supports quality checks so operators can catch variations early.

Better Workflow Efficiency

A precision bench scale responds quickly. It helps operators finish weighing tasks faster. It also reduces the time spent rechecking inconsistent numbers.

Precision Bench Scale vs. Standard Bench Scale

A standard bench scale focuses on capacity. It handles heavy items but does not offer high resolution.

A precision bench scale focuses on fine measurement. It highlights small difference detection, repeatability, and stable readings. This difference makes the precision bench scale the correct choice for tasks that depend on accuracy instead of heavy capacity.

Key Differences

- Higher resolution

- Lower fluctuation

- Better control in testing environments

- More suitable for small components and samples

Applications of Precision Bench Scales

Electronics and Small Parts Manufacturing

Industries that handle micro-parts or PCBs depend on weight accuracy. A precision bench scale helps track component weights, sort items, and control manufacturing steps.

Laboratory Research and Sample Testing

Labs need consistent measurements when preparing samples or testing formulas. A precision bench scale supports these tasks with stable readings that remain accurate after continuous use.

Jewelry and Metal Processing

Jewelry workshops rely on accurate weighing of gemstones, precious metals, and small crafted pieces. A precision bench scale ensures each measurement remains consistent.

Food Development and Small-Batch Processing

Small test batches often require exact weight control. A precision bench scale helps maintain consistency during recipe trials and ingredient adjustments.