Durable Compact Food Processing Bench Scales

Dwinley’s food processing bench scales are designed for precise measurements, portion control, and recipe management. Built with durable, hygienic materials, they ensure efficient, accurate operations in food processing, ideal for packaging and portion monitoring.

Key features:

- Stainless steel and plastic plate

- Can use indoor or outdoor

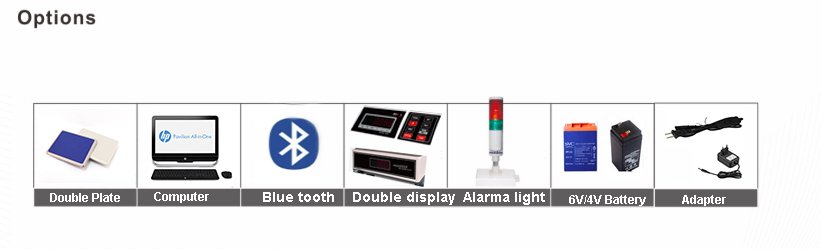

- WithBlue tooth and Wireless

- Programmable to meet your needs

- 4V or 6V battery choice

- Aluminum strong support bracket protect load cell

- Options: RS-232,Blue tooth,Alarm light,Wireless

Specifications of Food Processing Bench Scales

| .Display | 0.8″LED digit display |

| .Capacities | 3kg~30kg |

| .Pan Size | 210x260mm |

| .Keyboard | 8keys |

| .Unit | kg/g/lb |

| .Housing | ABS plastic |

| .Max. Divisions | 30,000d |

| .Operate Tem | 0ºC ~ +40ºC |

| .Power | AC adapter(8v/500mA),internal rechargeable battery (6V/4Ah) |

| .Gross weight | 3.0kg |

| .Packing | Master carton packing,dimension 0.016m³ |

| Master carton 4 in 1 packing,dimension 0.078m³ |

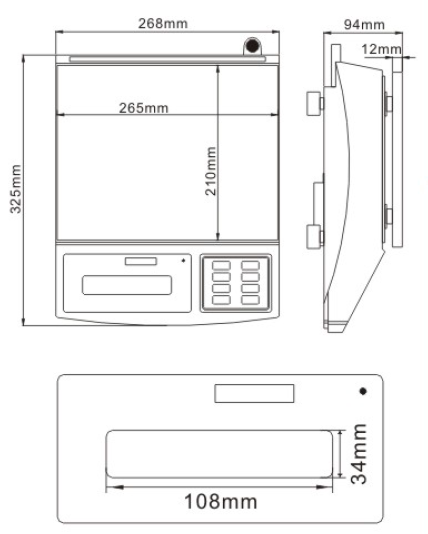

Dimensions(mm)

| Model Number | Capacity | Readability | Division | Approval |

|---|---|---|---|---|

| JCS-3B | 3kg | 0.1g | 30,000d | CE |

| JCS-6B | 6kg | 0.2g | 30,000d | CE |

| JCS-15B | 15kg | 0.5g | 30,000d | CE |

| JCS-30B | 30kg | 1g | 30,000d | CE |

Dwinley Food Processing Bench Scale Detail Display

Get a Bulk Pricing Quote for Food Processing Bench Scales

The right food processing bench scales help maintain portion accuracy, support hygiene programs, and keep production flowing. Dwinley supplies durable, washdown-ready models designed for the daily demands of modern food processing rooms. Ideal customers include wholesalers, distributors, and factories running multiple processing lines, especially those that require consistent bulk supply.

The Role of Bench Scales in Food Processing

Bench scales play a central role in food processing. Workers use them for portioning, batching, packing, and quality checks. Food production lines move fast. Every step depends on reliable weight control. A bench scale must handle moisture, raw ingredients, and frequent cleaning. In many plants, stainless steel construction supports these tasks. The main focus, however, remains accurate and stable weighing in real production rooms.

Environmental Conditions in Food Processing

Food processing rooms create harsh conditions for weighing equipment. Water sits on tables and floors. Steam appears near cooking and mixing stations. Cold rooms cause condensation on metal parts. Raw meat, seafood, dough, and vegetables leave residue on platforms. Conveyor lines and cutters create vibration. A bench scale must stay accurate under all these influences. It must also tolerate long shifts and rough handling.

Key Requirements for Food Processing Bench Scales in Food Processing

Hygiene and Cleanability

Food processing requires strict hygiene. Bench scales must handle frequent washdown. The platform should stay smooth and easy to clean. Stainless steel helps because it resists corrosion and supports food-contact safety. A sealed body reduces residue buildup and protects internal parts from moisture.

Accuracy and Stability During Weighing

Food production relies on accurate readings. Bench scales need fast response and stable sensors. Vibration, steam, and temperature changes should not affect performance. Clear displays help operators work in wet or cold rooms.

Portion Control and Yield Efficiency

Portion control protects yield. Even small overfill increases cost. Bench scales with quick stabilization and check-weighing cues help operators reach targets with less waste.

Product Consistency and Quality Control

Consistent weight supports product quality. Stable readings ensure uniform portions for ready meals, bakery items, and frozen foods. This reduces rework and quality complaints.

Digital Integration and Traceability

Food factories rely on data. Bench scales can connect to printers and software. Automatic weight records support traceability, reduce manual errors, and help managers monitor performance.

Why Stainless Steel Scale Supports Food Processing

Stainless steel construction helps bench scales survive food processing conditions. It resists chemicals, saltwater, and cleaning agents. The surface stays flat after heavy use. This keeps the platform mechanically stable. Stainless steel does not absorb liquids or hold bacteria when cleaned correctly. These qualities support hygiene programs and extend service life in wet and aggressive environments.

Key Factors When Selecting Food Processing Bench Scales

When selecting bench scales for food processing, focus on features that support accuracy and reliability in wet, high-demand environments. Capacity should match the heaviest trays on the line, while resolution needs to support precise portion control. Platform size must fit common containers to ensure stable weighing.

A suitable waterproof rating is essential for washdown areas. Clear display visibility improves speed in steam or cold rooms. Data output options should integrate with labeling or traceability systems to keep production records consistent and efficient.