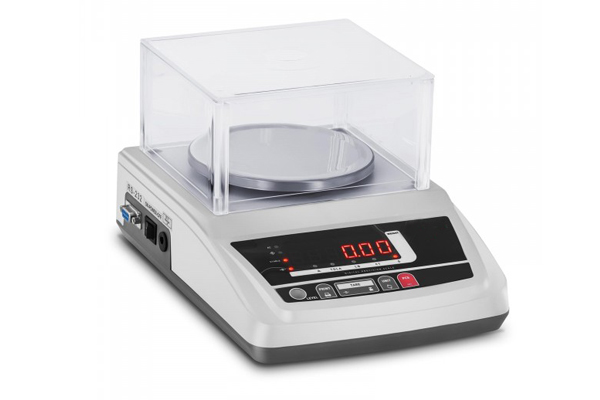

High Quality Precision Balance China Manufacturer & Supplier

Dwinley manufactures precision balances for laboratories, universities, and industrial facilities. Our balances combine accurate measurement with durable design, making them a reliable choice for routine testing and quality control. As a wholesale manufacturer, we also support customized solutions to meet different requirements.

- Readability from 0.001 g to 0.1 g for accurate results

- Digital display for clear and fast readings

- Options with draft shields to reduce air interference

- Durable construction for long-term use in labs and production environments

- Available for OEM and customized configurations

- Weighing results can be transmitted to a computer in real time for recording, analysis, or archiving.

Dwinley Precision Balance Scale Series

Our precision balances are designed for professionals who need accuracy and efficiency. Each unit provides stable readings and handles larger weighing capacities, which makes them versatile for a wide range of tasks.

As a direct manufacturer, Dwinley ensures consistent quality at competitive prices. Our production process focuses on stability, digital accuracy, and long service life. We also provide custom manufacturing options, allowing clients to add features or brand the equipment for their own markets.

Benefits and Applications of Precision Balances

- Flexible Accuracy and Capacity – Our scales offer a range of precision and capacity options, allowing users to select the ideal combination for different weighing tasks. This ensures reliable and repeatable measurements whether handling tiny samples or larger quantities.

- Multiple Weighing Units – With support for grams, carats, pounds, ounces, and more, these balances adapt to diverse professional applications, including laboratory experiments, jewelry measurements, and industrial weighing. Users can switch units quickly to meet specific needs.

- Durable Construction – Built with stainless steel plates, plastic housing, and a protective glass shield, the scales withstand daily wear and tear while safeguarding sensitive internal components, resulting in long-term reliability.

- Easy Operation – Backlit LCD display provides clear readings, while the intuitive keyboard minimizes user errors. Frequent or complex weighing tasks become simpler and faster, reducing mistakes and improving efficiency.

- Safety and Convenience – Features such as tare, zero tracking, overload protection, automatic calibration, and programmable settings enhance both measurement accuracy and operational safety, making the scales suitable for repetitive or precise work.

- Data Management and Connectivity – Optional RS-232 interface allows seamless connection to computers, printers, and other devices. This simplifies data recording, reporting, and workflow automation in professional environments.

- Certified Quality – CE certification guarantees compliance with international safety and quality standards, assuring users that the scales are reliable, accurate, and meet regulatory requirements.

- Research laboratories and universities

- Chemical and pharmaceutical testing

- Food quality control and analysis

- Industrial production and manufacturing processes

- Educational institutions for training and research

Analytical Balance vs Precision Balance

| Feature | Analytical Balance | Precision Balance |

|---|---|---|

| Typical Capacity | 60 g – 320 g | 200 g – 30,000 g |

| Readability (d) | 0.0001 g (0.1 mg) | 0.001 g – 0.1 g (1 mg – 100 mg) |

| Draft Shield | Required | Optional depending on model |

| Environmental Sensitivity | Highly sensitive, requires controlled conditions | More robust to environmental influences |

| Calibration | Mostly internal automatic calibration | Internal or external calibration |

| Recommended Applications | High-precision analytical work, micro-weighing, pharmaceutical R&D | General weighing, formulation, quality control, education |

Why Choose Dwinley?

Dwinley ensures every precision balance undergoes strict quality control, delivering consistent accuracy and long-term durability. We focus on wholesale supply, meeting the needs of laboratories, educational institutions, and industrial clients with reliable, cost-effective solutions. Our OEM and customization services allow functional adjustments such as interfaces, printing options, and display configurations, so your equipment fits your workflow. With competitive pricing and proven performance across labs and industrial sectors, we balances quality, functionality, and value.

Partner with us today to secure precision balances that meet your exact requirements. Contact us for wholesale inquiries or customized solutions.