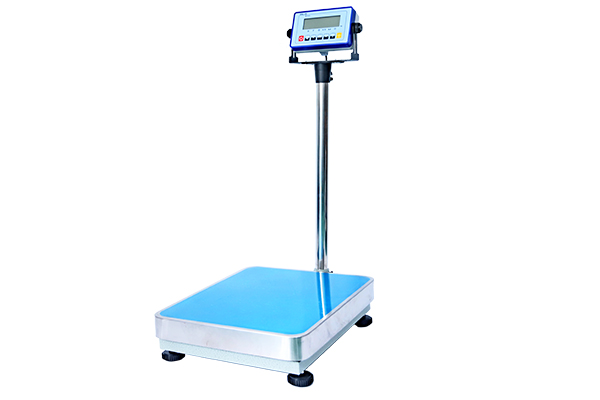

Role of Stainless Steel Platform Scales in Industrial Weighing

Typical Industrial Applications

Stainless steel platform scales appear in many sectors. Common examples include:

-

Food and beverage processing plants

-

Meat and seafood facilities

-

Chemical and pharmaceutical factories

-

Metal fabrication workshops

-

Logistics centers and warehouses

In these environments, operators weigh raw materials, work in progress, and final goods. The scale often sits on the floor. Forklifts, pallet jacks, and manual carts move loads on and off the platform all day.

The working conditions are often harsh. Floors stay wet. Cleaning crews spray hot water and detergent. Some areas see contact with acids, salts, or oils. Equipment that cannot handle this exposure fails quickly.

Why Stainless Steel Matters

Stainless steel offers three core advantages in these settings.

First, it resists corrosion. Moisture and cleaning chemicals do not damage the surface easily. This keeps the frame and platform stable over time.

Second, it supports hygienic design. Smooth stainless surfaces clean more easily than painted mild steel. Food and pharmaceutical plants often list stainless materials as a compliance requirement.

Third, it keeps structural integrity under repeated loading. Heavy pallets and containers bend weaker materials. Stainless steel frames maintain their shape and protect the load cells beneath the platform.

Because of these factors, stainless steel platform scales are not a luxury choice. In many industries they are the default option when hygiene and durability matter.

Product Characteristics That Drive End-User Preference

Durability Under Daily Abuse

Operators do not handle industrial scales delicately. Loads can drop onto the platform. Pallet trucks can hit the side. The platform may carry loads near its rated capacity for long periods.

A rigid stainless steel frame distributes these forces. It reduces deformation and protects the load cells. End users see fewer failures and fewer calibration issues. This is one reason many factories standardize on stainless steel designs over time.

Compatibility with Cleaning and Sanitation

In food, beverage, and pharmaceutical environments, cleaning is part of the daily schedule. Teams wash floors and equipment with high-pressure water. They apply foaming agents and disinfectants. Any remaining residue can cause safety issues.

Stainless steel platforms withstand these cleaning routines. They do not rust. They do not flake coatings. IP-rated load cells and junction boxes help keep moisture out of the electronics. For end users, this means less downtime and fewer replacements.

Fit with Regulatory and Audit Requirements

Many regulated industries must show that their equipment supports hygiene and process control. Stainless steel construction helps meet audit expectations. Platform scales often sit inside production or packing areas where inspectors pay close attention.

Because of this, the product category has long-term demand. End users rarely “trade down” to cheaper but less suitable designs once they understand the risk.

How Industrial Buying Behavior Shapes Distributor Strategy

Small-Quantity Purchasing Patterns

Most industrial end users do not buy dozens of scales at once. They purchase in small batches, often between one and five units. Typical situations include:

-

A new production line starts operation

-

A damaged scale needs replacement

-

A plant adds extra weighing points in a packing hall

-

A warehouse expands a shipping area

These events happen throughout the year. The result is a stream of small orders rather than a few large one-time projects.

For a manufacturer, many scattered small orders create handling cost and production complexity. For a distributor, this pattern is ideal. Distributors buy larger quantities from the factory and break them into small shipments for their customers.

Urgent Replacement Needs

When a key floor scale fails, production or shipping can slow down or stop. Many end users do not accept long lead times. They expect quick replacement, sometimes within the same day or week.

This expectation makes local or regional stock very important. Distributors can respond faster than factories because they hold inventory close to the end user. Wholesale stainless steel platform scales therefore match both the volume model of the manufacturer and the speed expectations of the user.

Preference for Standardized Solutions

Most buyers do not want to engineer a custom platform scale every time. They prefer standard sizes and capacities that technicians already know. Stainless steel platform scales fit this pattern well. The category relies on a stable set of formats.

This standardization makes it easier for distributors to hold stock. It also reduces the technical risk when selling to new customers.

Market Demand and Its Impact on Wholesale Decisions

Broad Industry Coverage

From the product side, stainless steel platform scales already have strong reasons to exist. From the market side, their broad coverage multiplies demand.

One distributor can sell to:

-

Food factories that wash equipment daily

-

Cold stores that run near freezing temperatures

-

Chemical plants that use aggressive cleaning agents

-

Heavy workshops that need robust platforms

Because one product type crosses so many verticals, distributors can use the same inventory base to serve different segments. This reduces the chance of slow-moving stock and dead inventory.

Growing Sectors Increase Baseline Demand

Several sectors that rely on stainless steel platform scales continue to expand. These include cold chain logistics, e-commerce warehousing, packaged food, and ready-to-eat products. Every new facility adds weigh points. Older sites add more as they scale.

This growth increases the number of installed units in the market. As installed base rises, replacements and upgrades follow. Distributors look at this installed base and see a steady demand flow for wholesale stainless steel platform scales.

Why Distributors Choose Wholesale Stainless Steel Platform Scales

Alignment with “Small Order, Many Times” Business

The main operational model for many distributors relies on frequent small orders from customers. Stainless steel platform scales fit this model perfectly. One pallet of wholesale inventory can cover many orders over several weeks.

Distributors can allocate scales across different clients. They do not need huge warehouse space. They can also manage cash flow more smoothly because each outgoing order is relatively small but consistent.

Healthy Margin Structure

Stainless steel scales are not purely price-driven products. Buyers value durability, hygiene, certification, and brand reputation. This allows more rational pricing than low-end mild steel units.

Distributors can set margins that reflect the value to the customer. They avoid extreme price wars that often appear in lower-spec categories. At the same time, the price gap versus non-stainless models is easy to explain to buyers.

Manageable Inventory Complexity

The product line uses a limited set of standard platform sizes and capacities. Distributors can structure their stock around a small number of core SKUs. For example:

-

600 × 600 mm, 300–600 kg

-

800 × 800 mm, 600–1,500 kg

-

1,000 × 1,000 mm, 1–3 tons

This keeps stocking simple and forecasting realistic. It also reduces the risk that a large portion of inventory will not match current demand.

Long Shelf Life

Stainless steel frames do not rust in storage. Properly sealed load cells keep moisture out. As a result, scales can sit in a distributor warehouse for extended periods without damage.

This long shelf life reduces inventory risk. A distributor can place a wholesale order with a factory and know that the product will remain saleable over a long horizon.

Moderate After-Sales Burden

Distributors review not only sales potential but also service workload. Stainless steel platform scales are relatively simple systems. Common service actions include:

-

Replacing a damaged load cell

-

Changing a faulty indicator

-

Re-calibrating after heavy impact

These tasks do not require large engineering teams. A small technical group can manage service for many installed units. Low after-sales burden makes the product attractive at scale.

OEM and Customization Opportunities for Distributors

Private Label Options

Many manufacturers of stainless steel platform scales support private label programs. Distributors can place their own brand on the product. This helps them build market identity and long-term customer loyalty.

Under such programs, the factory produces standard platforms and frames. The distributor controls labeling, documentation, and sometimes the indicator selection. This model gives the distributor more control over positioning and pricing.

Tailored Configurations

Some customers need specific platform sizes, capacities, or communication functions. For example:

-

Integration with ERP or MES systems

-

Higher IP ratings for wash-down zones

-

Special mounting options for harsh floors

Through OEM relationships, distributors can request such variations while keeping the core design stable. This allows them to answer complex project tenders without building a custom solution from scratch.

Practical Considerations for Distributors Planning Inventory

Mapping Local Industry Structure

Distributors should assess which industries dominate their region. Areas with strong food processing, cold chain logistics, or chemical production present higher potential for stainless steel platform scale sales.

A basic mapping exercise might include:

-

Number of plants in food and beverage

-

Size of logistics and warehouse clusters

-

Presence of pharmaceutical or biotech sites

-

Scale of metal fabrication and heavy industry

This information helps define how much wholesale volume to commit to.

Building a Tiered Product Portfolio

Distributors rarely sell only one type of platform scale. They often set up a tiered structure:

-

Entry level: painted mild steel for dry, light-duty use

-

Mid tier: stainless steel for standard industrial environments

-

High tier: stainless units with advanced indicators and high IP ratings

In this structure, wholesale stainless steel platform scales occupy the central role. They become the default choice for serious industrial users who balance cost and performance.

Service and Training Capability

Even with low after-sales burden, distributors need basic technical competence. This includes:

-

Installing and leveling scales

-

Performing routine calibration

-

Replacing load cells and indicators

Investing in this capability increases customer confidence and makes the product easier to sell.

Partner With Dwinley For Wholesale Stianless Steel Platform Scales

Dwinley focuses on industrial weighing solutions for demanding environments. We manufacture stainless steel platform scales designed for hygiene, durability, and stable performance. With wholesale supply, OEM options, and technical support for distributors, Dwinley helps partners serve end users across food processing, logistics, chemical, and general manufacturing sectors.