Best Counting Scale For Small Parts with Laboratory Weighing Function

Dwinley‘s small parts counting scales provide fast and accurate counting for tiny components such as screws, nuts, fittings, and electronic pieces. Thees scales calculate the average unit weight and converts the total weight into an exact quantity. This helps operators handle large batches efficiently during packaging, kitting, and inventory checks.

Key Features:

- High-Precision Sensors

- Programmable to meet your needs

- Battery Provice up to 70 hours of continuous use (without backlight)

- Optional RS-232 interface can connect to computer or external printer

- Fast Response and Real-Time Counting

- Durable Construction

Why Choose Dwinley Digital Scales For Counting Small Parts?

Reliable Accuracy for Small Components

Dwinley digital couting scales provide stable and repeatable measurements, making them a trusted small parts counting scale for screws, fasteners, and electronic components. The system minimizes miscounts and keeps daily operations consistent.

Faster Processing for Bulk Parts

Our digital counting scale for small items speeds up packaging and kitting by converting weight into quantity instantly. This helps teams handle large batches quickly without slowing production.

Reduced Labor and Workload

Dwinley reduces the need for manual counting, which saves time and lowers fatigue. Operators can focus on higher-value tasks while the scale handles repetitive quantity checks.

Prevents Overfilling and Short Deliveries

Choosing the best counting scale for small parts helps avoid inaccurate quantities in each package. Dwinley ensures you do not give away extra pieces or risk shipping fewer parts than required.

Improves Inventory Control

With accurate digital counts, warehouses complete stock checks faster and with fewer discrepancies. This supports better planning and smoother restocking cycles.

Flexible Options for Different Workflows

We offer custom capacities, pan sizes, and interface options, helping businesses create a small parts counting solution that fits their exact process requirements.

Specifications of Small Parts Couting Scales

| .Display | 15mm digit LCD display,with white LCD backlight |

| .Capacities | 3kg~30kg |

| .Pan Size | 210x260mm |

| .Keyboard | 16 keys |

| .Unit | kg/g |

| .Housing | ABS plastic |

| .Max. Divisions | 30,000d |

| .Operate Tem | 0ºC ~ +40ºC |

| .Power | AC adapter(8v/500mA),internal rechargeable battery (6V/4Ah) |

| .Gross weight | 3.0kg |

| .Packing | Master carton packing,dimension 0.016m³ |

| Master carton 4 in 1 packing,dimension 0.078m³ |

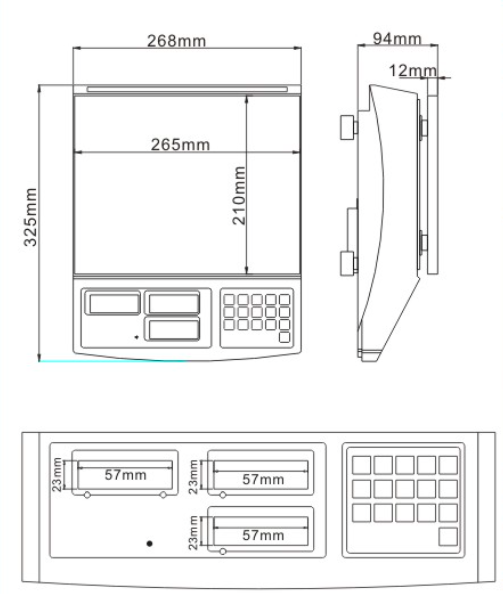

Dimensions(mm)

| Model Number | Capacity | Readability | Division | Approval |

|---|---|---|---|---|

| JCS-3A | 3kg | 0.1g | 30,000d | CE |

| JCS-6A | 6kg | 0.2g | 30,000d | CE |

| JCS-15A | 15kg | 0.5g | 30,000d | CE |

| JCS-30A | 30kg | 1g | 30,000d | CE |

Applications of Small Parts Counting Scales

- Fastener packaging: screws, bolts, washers, pins, and clips.

- Electronics manufacturing: resistors, capacitors, connectors, and micro-parts.

- Plastic components: molded fittings and lightweight pieces used in assembly.

- Warehouse inventory: cycle counting and stock verification.

- Kitting and production lines that require consistent part quantities.

Request Wholesale Pricing from Diwinley

Share your part size, weight range, and application needs, and our team will recommend the most suitable model with clear technical specifications and configuration options. We support wholesale supply with confirmed lead times, packaging details, and long-term stocking plans.

Understanding Small Parts Counting Scales

A counting scale for small parts uses weight-based calculations to determine quantity. When a user places a known number of parts on the platform, the device calculates the average unit weight. The scale then uses this value as the reference for future batches.

Workers rely on this method because it reduces labor time, minimizes human error, and creates a repeatable process for managing high-volume items. This approach works well for fasteners, stamped components, machined parts, molded plastic items, terminals, electronic components, bearings, and any small objects with tight weight uniformity.

A small parts counting scale can support both high-precision micro components and heavier metal hardware, but performance depends on selecting suitable readability, internal resolution, and capacity.

How Counting Scales Convert Weight into Quantity

Step 1: Sample Setup

The operator places a defined quantity of components on the weighing platform. Most production environments select 10, 25, or 50 pieces, depending on part weight. A larger sample improves accuracy because it reduces the effect of minor variations in individual pieces.

Step 2: Average Piece Weight Calculation

The scale divides the total sample weight by the number of items. This becomes the internal reference value. High-quality counting scales use advanced load cells and fast signal processing to calculate stable unit weights even when the components are extremely light.

Step 3: Counting the Full Batch

When the operator loads the entire batch, the scale divides the total weight by the stored unit weight and outputs the part count. Advanced models also display total weight and unit weight simultaneously, giving operators a clear overview during the process.

The accuracy of a counting scale for small parts primarily depends on its load cell resolution and the uniformity of the components themselves.

Why Weight-Based Counting Outperforms Manual Counting

Speed

Factories and warehouses often need to verify hundreds of part SKUs each day. Weight-based counting compresses a multi-minute manual process into a few seconds.

Error Reduction

Even trained teams introduce miscounts under pressure. A counting scale maintains consistency across shifts, operators, and locations.

Inventory Traceability

Consistent count accuracy supports procurement planning, demand forecasting, and quality audits. It also reduces stock discrepancies that disrupt production.

Efficient Packaging and Kitting

When building kits or packing pre-set bag quantities, weight-based counting prevents shortages that lead to customer complaints and rework.

These performance improvements explain why many buyers view a small parts counting scale as essential equipment for production and warehouse teams.

Key Features to Look For in the Best Counting Scale for Small Parts

- High-Precision Load Cells

- Essential for detecting tiny weight changes and maintaining repeatable accuracy.

- Fast Response Time

- Instant updates help operators process large batches without delay.

- Durable Industrial Housing

- A strong structure ensures stable performance during daily use in factories and warehouses.

- Multiple Operating Modes

- Counting, weighing, and accumulation modes support various workflows.

- Clear, Easy-to-Read Display

- Large numeric screens reduce operator errors and improve efficiency.