Accurate counting of small parts is a critical factor for businesses managing high volumes of components. A reliable counting scale reduces errors, ensures precise inventory control, and improves overall efficiency. With so many models and features available, selecting the right scale requires understanding capacity, accuracy, and ease of use. This guide helps businesses identify the best counting scale for small parts and make informed decisions that save time and costs.

Why the Right Counting Scale Matters

Accuracy for Small Parts

A counting scale plays a critical role in parts counting. Small parts often weigh very little, so even a minor error can lead to big mistakes. High accuracy ensures that every piece gets counted correctly. This level of precision helps companies avoid costly shortages or overages.

When workers use a scale designed for small parts, they see fewer errors in their daily tasks. The right scale detects even the smallest weight differences. This feature prevents miscounts and supports reliable inventory management.

Tip: Always check the scale’s resolution before buying. Higher resolution means better accuracy for small items.

Inventory Efficiency

A business that invests in the right counting scale improves workflow. Employees spend less time double-checking counts and more time on productive tasks. Fast and accurate counting speeds up inventory checks and order fulfillment.

Efficient inventory management depends on reliable equipment. A scale that matches the needs of small parts reduces manual work. Workers trust the results and avoid time-consuming recounts.

Accurate counting leads to:

- Fewer inventory errors

- Faster stock audits

- Better customer satisfaction

Choosing the correct scale for small parts transforms the entire inventory process. Companies see fewer mistakes and smoother operations. The right equipment supports both accuracy and efficiency, making it a smart investment for any business.

Features to Compare in a Counting Scale

Capacity and Resolution

Capacity and resolution shape the performance of any counting scale. A scale must handle loads that exceed the largest batch of small parts a business expects to count. For example, if a company often counts batches of 500 screws, the scale should support at least 600 to avoid overloads.

Resolution matters most for small parts. High resolution allows the scale to detect tiny weight differences. This feature prevents miscounts and supports accurate parts counting. A scale with high resolution delivers reliable results every time.

Tip: Choose a scale with capacity above your typical load and high resolution for best results.

| Feature | Why It Matters | Example Use Case |

|---|---|---|

| Capacity | Prevents overloads | Counting large batches |

| Resolution | Detects small changes | Counting tiny screws |

Sample Size Setting

Sample size settings improve efficiency and accuracy in counting. Workers set a sample size to teach the scale how much each part weighs. A flexible sample size setting lets users adjust for different types of small parts.

A scale with easy sample size adjustment saves time. Employees switch between parts without confusion. This feature reduces errors and boosts productivity.

Note: Always define the sample size carefully to ensure accurate counting.

Price and Brand Reputation

Price and brand reputation influence the value of a counting scale. Buyers should compare prices to find the best counting scale for their budget. A higher price often means better durability and advanced features.

Brand reputation signals reliability. Customers trust brands with positive reviews and proven durability. Reading user reviews helps buyers avoid poor-quality products.

Key factors to consider:

- Price range

- Durability

- Customer feedback

A wise buyer invests in a counting scale that balances cost, durability, and reputation. This choice supports long-term success in parts counting.

Tips for Choosing the Best Counting Scale

Matching Scale to Usage

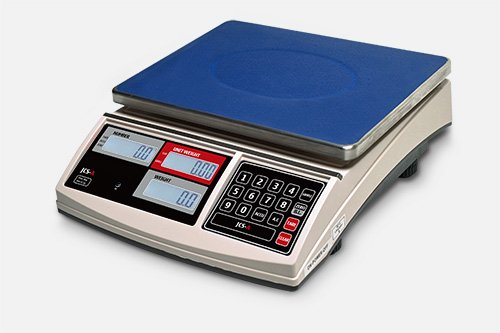

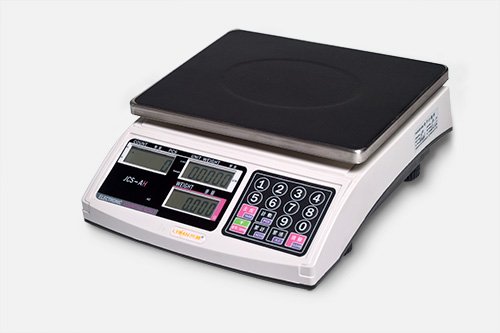

Selecting the best counting scale starts with understanding how often workers perform counting tasks. Frequent counting of small items demands a durable scale with a user-friendly interface. Companies that handle a wide range of small items should look for easy-to-use bench scales that allow quick switching between parts.

Tip: Always match the scale’s capacity and resolution to the size and weight of the small parts. This approach ensures reliable measurements and smooth parts counting procedures.

Consider these factors to consider:

- Frequency of counting tasks

- Variety of small items handled

- Need for portability or fixed placement

Choosing the right scale for the job leads to faster and more accurate counting.

Error Reduction Strategies

Accurate counting depends on minimizing errors. Regular calibration keeps the scale precise. Workers should define the sample size carefully for each batch of small items. This step prevents miscounts and supports consistent results.

Note: Training staff on proper parts counting procedures reduces mistakes and boosts confidence.

Key factors to consider for error reduction:

- Schedule routine calibration

- Use clear sample size definitions

- Provide staff training on counting

These strategies help companies achieve reliable results every time.

Technology and Connectivity

Modern counting scales offer advanced technology features. Data storage and transfer options make inventory tracking easier. Many scales connect to computers or inventory software, streamlining parts counting and reporting.

A user-friendly interface helps workers operate the scale with less training. Easy-to-use bench scales with digital displays save time and reduce confusion. Companies that value efficiency should look for scales with software compatibility and USB or wireless connectivity.

Companies that invest in technology features gain better control over inventory and improve workflow.

When evaluating the best counting scale, consider these factors to consider:

- Data storage and export options

- Compatibility with inventory software

- Ease of use and display clarity

Smart choices in technology lead to better counting and inventory management.

Conclusion

Choosing the best counting scale for small parts improves accuracy and saves time during inventory taking. Buyers should compare capacity, resolution, sample size settings, price, and brand reputation. A smart investment in reliable equipment supports efficient parts counting and reduces costly mistakes.

- Assess specific needs before purchasing

- Research features and user feedback

- Select a scale that matches daily workflow

The right scale helps companies achieve better results and maintain control over inventory.